2025 Global Building Block Toy Industry Panorama

I. Market Scale Hits a New High: Asia-Pacific Leads, Emerging Markets Surge Collectively

The global building block toy market achieved milestone growth in 2025, with the scale officially exceeding 14 billion US dollars (a year-on-year increase of 16.7% from 2024). The compound annual growth rate (CAGR) has remained stable at around 7.5% over the past five years, and it is expected to further climb to 25 billion US dollars by 2030.

The regional pattern shows a distinct feature of “Asia-Pacific dominance and multi-polar rise”:

- The Asia-Pacific region accounts for 64% of the global market with a scale of 9 billion US dollars. China, as the core engine, saw its market scale exceed 43 billion yuan RMB (year-on-year growth >12%), contributing nearly half of the Asia-Pacific sales.

- Southeast Asia: Driven by RCEP tariff reductions, imports surged 37.6% year-on-year. Vietnam and Thailand’s imports jumped 42% and 39% respectively, with the regional market breaking 1.2 billion US dollars for the first time.

- Middle East: Supported by Saudi Vision 2030, the market reached 680 million US dollars (growth rate 29%), led by demand for architectural building blocks.

- Latin America: Brazil contributed 60% of regional sales; genuine product penetration rose from 40% to 48%, despite counterfeit challenges.

II. Consumption Structure Reconstructed: Adult Players Become the Main Force, Driven by Intelligence and Guochao

The “all-age” trend was fully formed in 2025:

- Teenagers and adults aged 13-25 accounted for 35% of consumers, with those over 18 contributing 63% of mid-to-high-end product turnover.

- High-end sets (priced above 300 yuan) saw 217% year-on-year sales growth. Domestic brands like Sembo’s “Mechanical Gear” series and international brands like LEGO’s “18+” series were in short supply, fueling the “stress-relief economy”.

Two core demand drivers emerged:

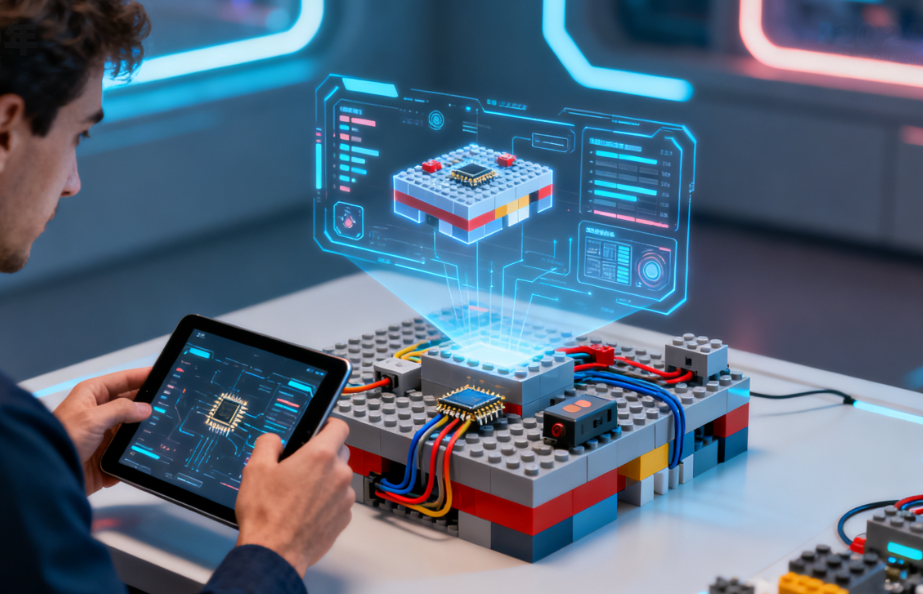

- Smart building blocks: Penetration rate soared from 15% (2022) to 45%. Global patent applications for programmable blocks rose 68% year-on-year, with Chinese manufacturers contributing 41%. IoT-equipped products became mainstream.

- Guochao IP co-brands: Domestic original IP products accounted for 42.3% of sales. Forbidden City/Dunhuang co-brands had a 43% repurchase rate, and 24 Solar Terms sets saw 82% export growth (25-30% price premium over ordinary products).

Educational building blocks also thrived, with 31.5% penetration in kindergartens and lower primary schools, contributing 6.8 billion yuan (26.7% of China’s total market).

III. New Brand Competition Pattern: Domestic Brands Surpass, Global Game Intensifies

The global market ended international brand monopoly:

- Domestic brands seized 52% of the global market share (doubling 2020’s figure). Sembo, Qman, and Bloks entered the global top 10; Qman’s Forbidden City co-branded products achieved 300 million yuan in annual sales.

- LEGO maintained a 19% global share but slowed to 6.8% growth in China, with 2025 sales at around 14 billion yuan (lagging domestic brands).

Differentiated strategies:

- International brands (LEGO): Focus on AR/VR (e.g., HoloLens sets with Microsoft) and global IP (Disney, Star Wars) to hold high-end markets.

- Domestic brands: Expand globally with cost advantages (45-60% of international brand prices) and localized IP. 2025 exports exceeded 800 million US dollars (year-on-year growth 21%), with Southeast Asia accounting for 38.6%. Pop Mart’s DIMOO series hit 100 million yuan in Southeast Asia in its first month.

Industry M&A heated up, with 3.5 billion US dollars in deals in H1 2025, focusing on IP operation and smart technology.

IV. Tech & Supply Chain Transformation: Eco-Intelligence Accelerates, Regional Layout Optimized

Technological innovation became a core barrier (leading enterprises’ R&D ratio rose to 8-10%):

- Eco-materials: Bio-based PLA usage increased from 12% (2022) to 23%. EU CBAM made carbon footprint certification mandatory for exports, enabling a 25% price premium.

- Smart interaction: IoT-equipped building block shipments reached 12 million sets; temperature/humidity sensors became standard for mid-to-high-end products.

- 3D printing: Application rate hit 18%, shortening R&D cycles from 45 to 28 days and boosting customer unit prices by 58%.

Supply chain regionalization:

- North America: 15 multinationals set up factories in Mexico, raising localization rate from 73% (2023) to 81%.

- China: Invested over 1.5 billion yuan in Vietnam’s raw material bases, forming a network covering the Pearl River Delta, Yangtze River Delta, and Southeast Asia.

Channel shift: Global live e-commerce accounted for 35% (39% in China). Douyin/Xiaohongshu unboxing content drove 43.6% growth in unplanned purchases; brand independent stations had a 2.3x higher repurchase rate than comprehensive platforms.

V. Opportunities & Challenges: Cost Pressure vs. Growth Dividends

Key Challenges

- Cost: ABS plastic spot price stood at 14,000 yuan/ton (year-on-year +8.7%); EU’s new Toy Safety Directive increased inspection costs by 18-25%, squeezing SMEs.

- IP disputes: Counterfeits caused genuine enterprises to lose 12% of potential revenue, especially in emerging markets.

Core Opportunities

- Sinking markets: China’s third/fourth-tier cities saw 65% order growth; central/western regions’ market share rose to 28%.

- Education integration: Global STEM building block government procurement is expected to triple in three years.

- Tech premium: Intelligent products had an 18-percentage-point higher profit margin than traditional ones.

Future investment will focus on three areas: original IP brand owners, eco-intelligent tech manufacturers, and Southeast Asia-focused channel operators. Southeast Asia’s channel construction is projected to yield a 28% ROI, becoming the new global growth hub.